Since my initiative to get this damn car together has set in, I've jumped into high gear ordering the remaining engine parts that I will need.

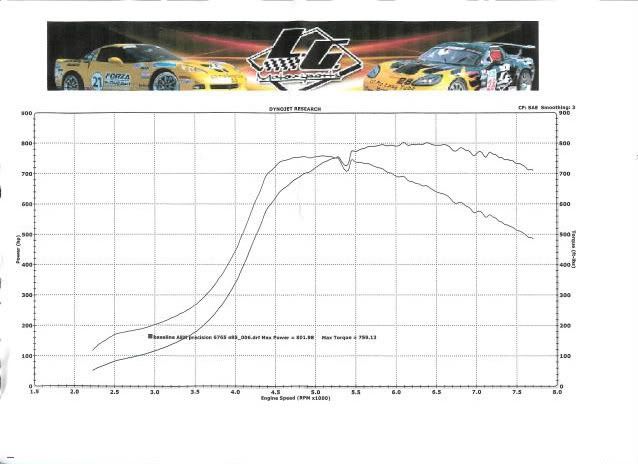

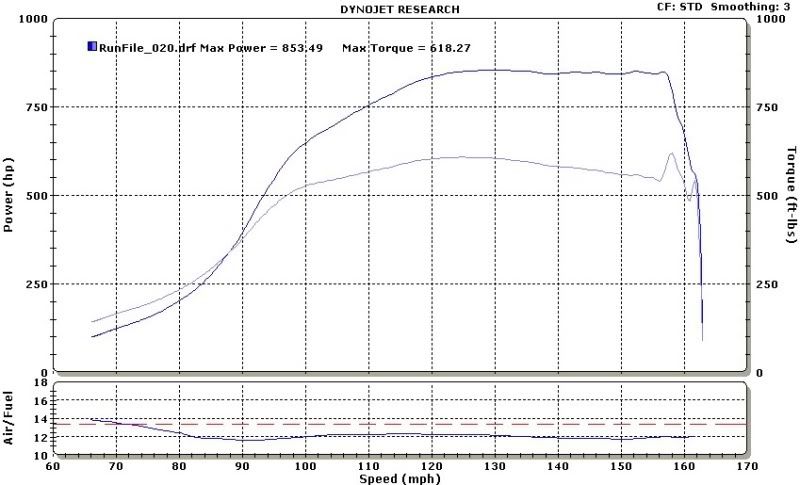

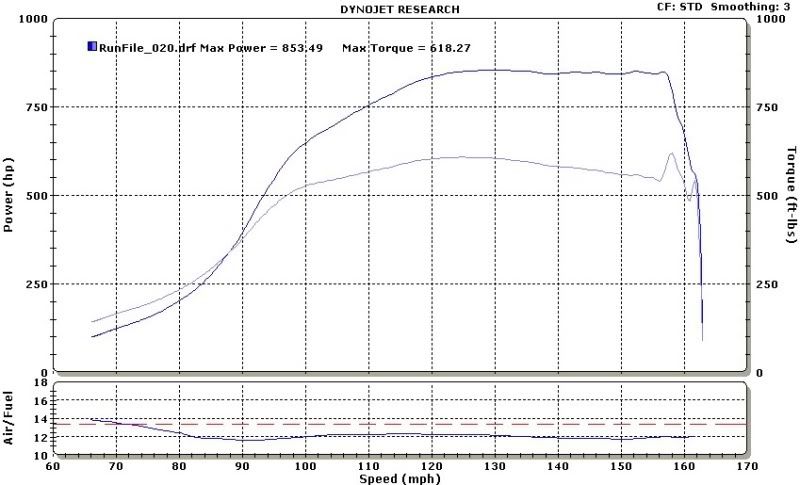

Tonight I purchased a Jun Style Intake Manifold with Q45 Throttle body for my 2JZGE. These have been proven by Big Daddy Performance to work very well. They are also very affordable off of ebay. Here is a picture of BD's S14 w/ a 2JZ swap. It uses the same intake and exhaust manifold that I have on order. He's using a GT4276 turbo. The below dyno chart is at 30psi on E85. I'm hopeful that I can achieve similar results with my build in terms of the power band. Here is a video of his latest drag racing pass:

http://www.youtube.com/watch?v=abb5g_49lcw

I've been trying to determine what fuel injectors to use on my ethanol powered powerplant. Ethanol takes 30% to 40% more fuel per horsepower when compared to gasoline. This means for me to make 1000hp on ethanol, I will need ~1350hp worth of fuel injectors. I've been shopping the market and everything in this size is expensive. I narrowed my selection down to 3 possible options:

1) Run One 220lb/hr low impedence simens injector per cylinder. This would make me have to run a injector driver due to the resistance of these injectors being lowered then the ECU can drive. This would run an additional $300 on top of the price of injectors. These injectors cost $160 per injector + shipping. So my total for this option would be $1260 + shipping.

2) Run Two 100lb/hr high impedance injectors per cylinder. The primary injector would run all the time with the secondary injector coming on under boost. This would get me the driveability I'm after while still providing the required volume of fuel while in boost. The trouble is I only have 10 injector drivers, and would again have to run a injector drive box with this option. So its the same cost as the above option in the end with more complexity.

3) Run One 220lb/hr high impedance injector per cylinder. This does away with the need for the injector drive box, and will supply plenty of fuel. The new high impedence bosch injectors out on the market have very good control down the 1 millisecond. This will allow me to idle at a good air fuel ratio, yet having the flow for as much as 1500hp on ethanol. The only snag on these is they run $240 per injector plus pig tails through Injector Dynamics. They were the company that released these products to the general racing public. I just got word that Fuel Injector Clinic was selling the identical injector for less. They sell them for $195 per injector with pigtails. Now we are moving in the right direction! More research on the internet turned up the following two pictures that clearly show the bosch part number that FIC is selling: 0 280 158 821. A quick search on google turned up another vendor selling these injectors for $149 per injector with adapter and pigtail. So with a little research I've saved myself about $600 over buying the ID2000 injectors.

FIC Bluemax 2150cc injector: