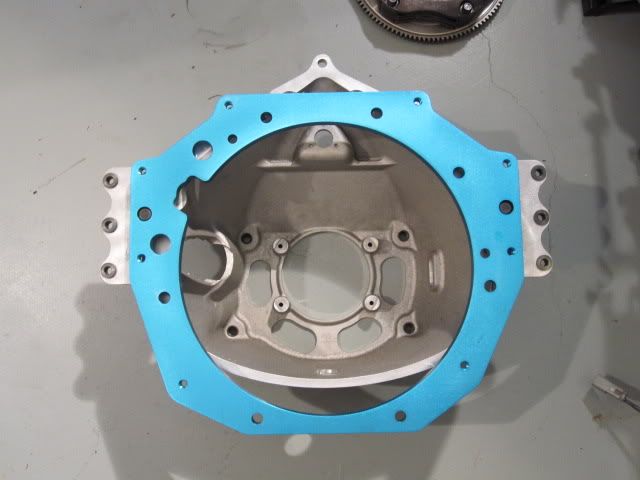

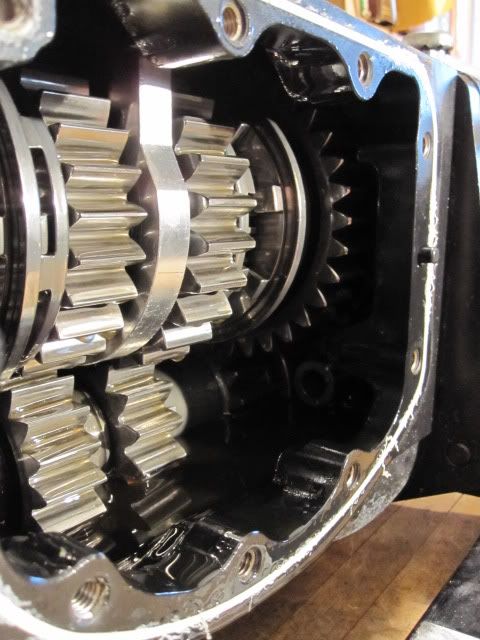

Been looking at adapter plates for both the EG33 and 2JZ to use the Dog box.

Here is my 2JZ analysis:

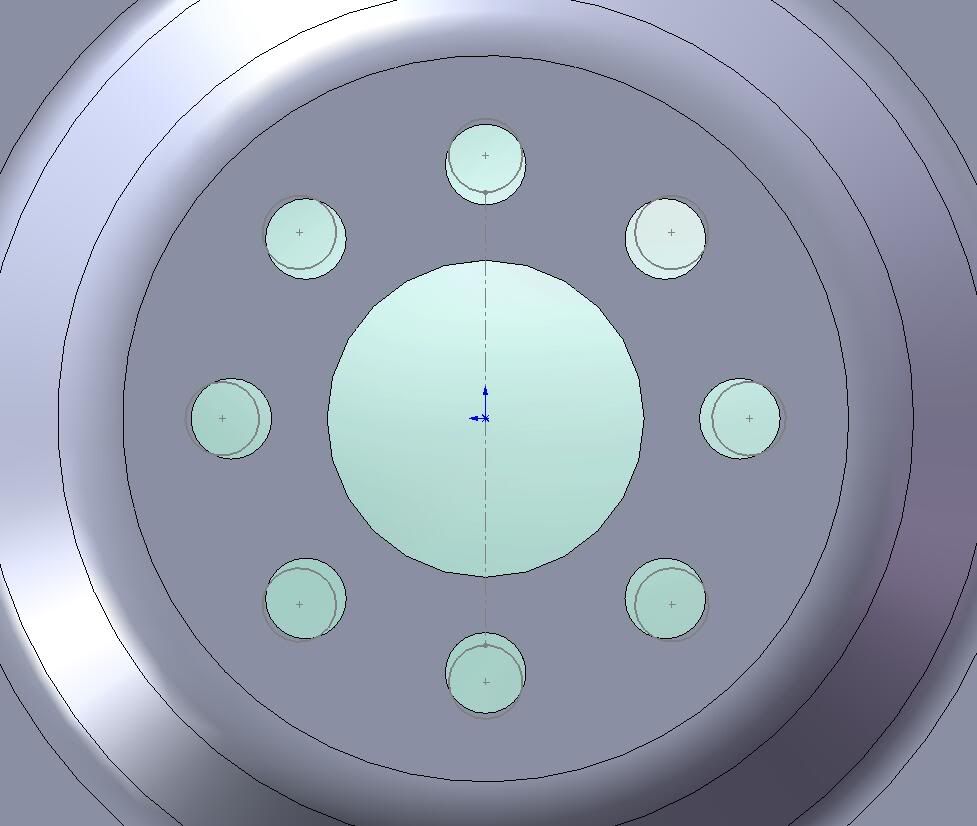

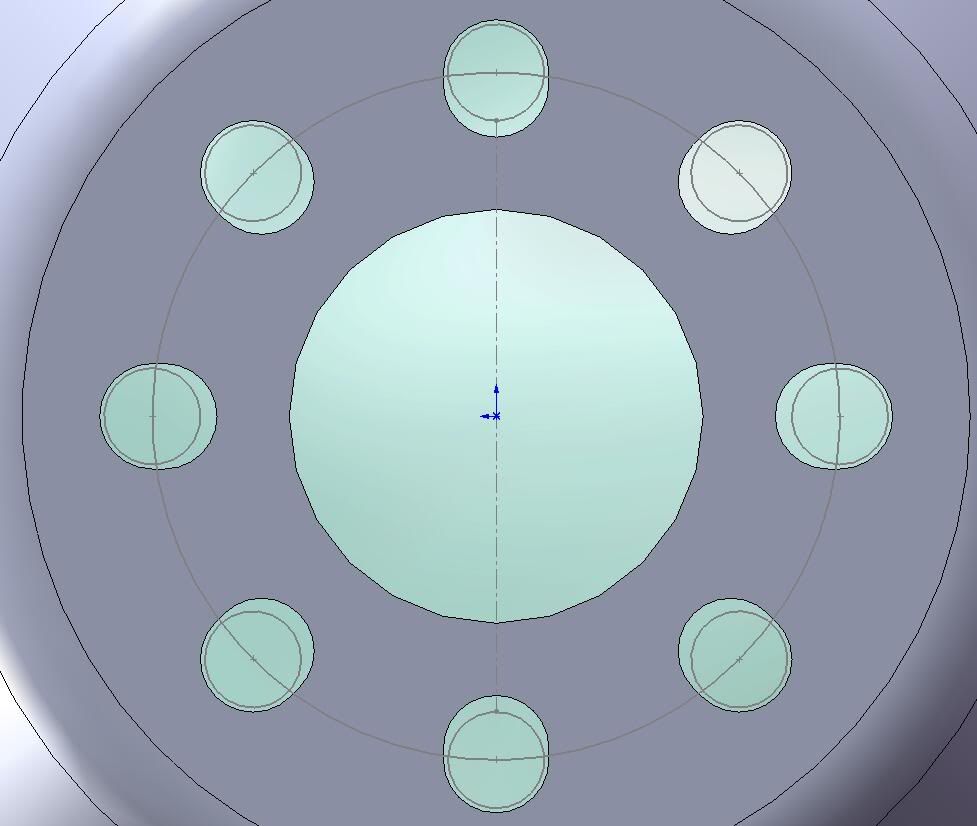

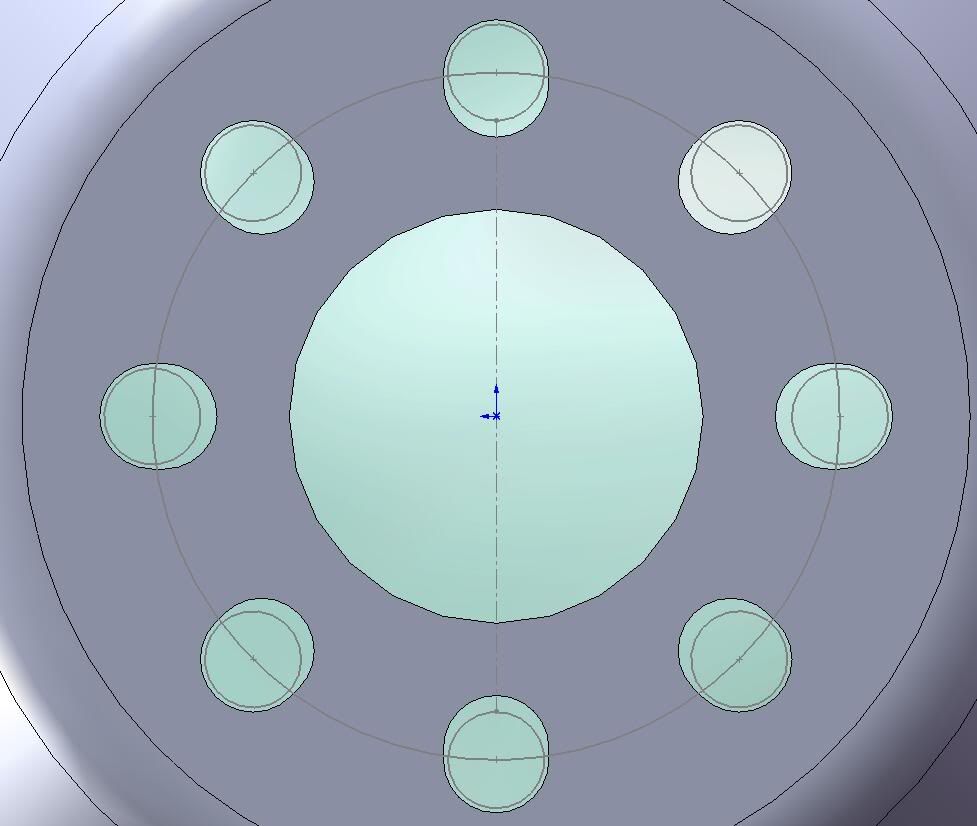

Comparing my Chevy R07 Flywheel (8 bolt pattern) to the standard 2JZ crank pattern, it would apprear they are very close in dimensions. I will likely do a little bit of machining on the flywheel and use a simple spacer between the crank and flywheel. Here is a picture of my Boostwerks TH400 crank adapter overlaying my Tilton flywheel.

Separate:

Adapter Over Flywheel:

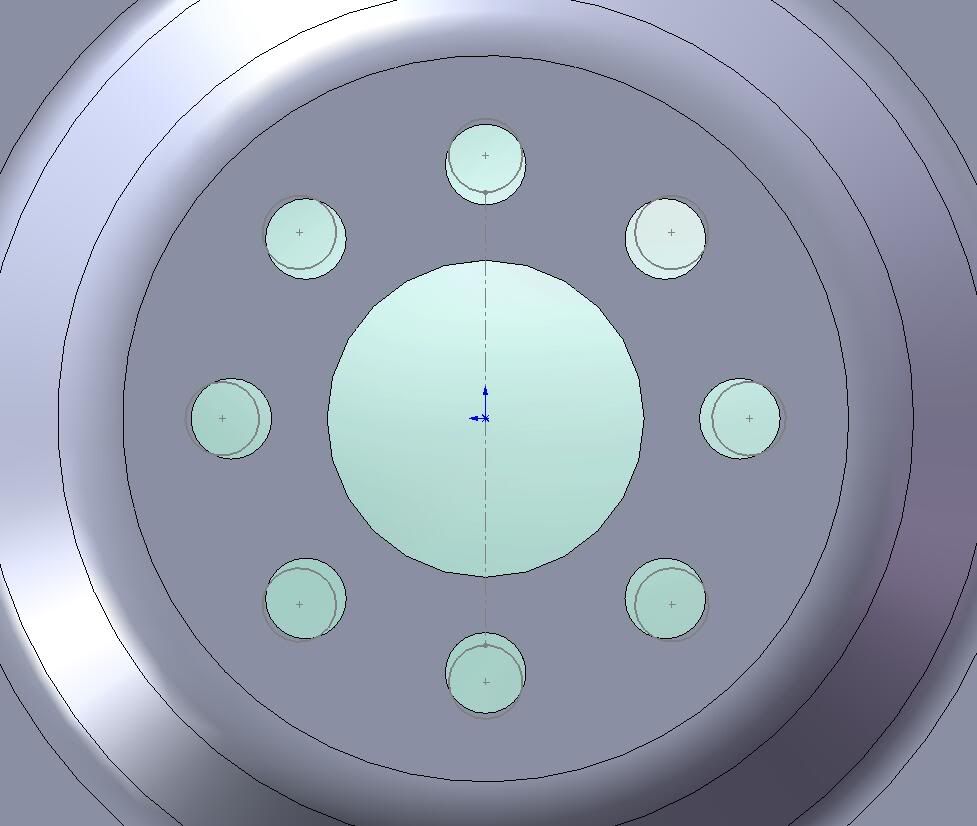

Tilton R07 Flywheel model with 2JZ bolt pattern sketched over the top:

The idea is to ovalize the mounting holes on the flywheel and use a 0.025" wall thickness bushing around the 10mm 2JZ crank bolts. This will allow everything to bolt together with a simple spacer.

I went to Tube Service today for some 2" square tubing. I'm redoing the rocker panels and welding in a temporary floor to get me rolling again. My welding will finally be returned to me after a 9 month lone to a family member. Never let family borrow your expensive tools. I was supposed to have this back in JUNE!!!!!!

I got the car back into the shop tonight, so it can dry out and await me working on it. Gotta love Thanksgiving week shutdown at work. Getting paid to work on my car is great! Having time to do it is priceless